x Are you new to the Logistics Industry and want to know exactly what JIT is?

x You don't clearly understand how to apply JIT to ensure the most effective and optimal results?

x Do you need to demonstrate through examples of practical JIT production applications in enterprises to easily visualize?

In the 4.0 era, Just-In-Time gradually becomes a popular term, when technology helps the manufacturing industry manage and adjust inventory monitoring processes and other activities, helping to shorten production time and Optimize related costs. Below, Proship.vn will give some examples of JIT production applications in practice for large enterprises as well as point out the practical benefits of JIT and the conditions for applying Just-In-Time. If you have ever heard about JIT but don't know how to apply it for optimal effectiveness, please update the content below.

📦 Hotline contact shipping

🧭 Central

What is JIT?

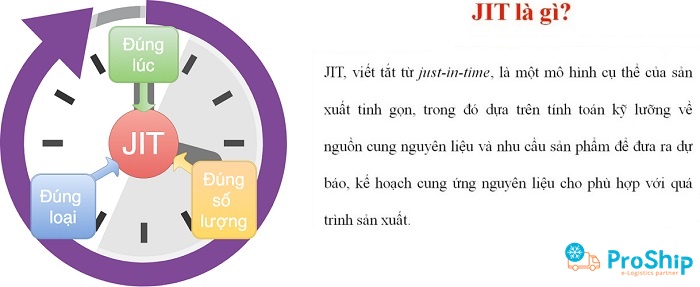

What is JIT? Just In Time (JIT) is also known as Just-In-Time strategy. This method requires Manufacturers to have the ability to accurately forecast demand and ordering/purchasing. In the simplest terms, Just-In-Time is the production of "Right product - Right quantity - Right place - Right time needed" . In JIT, processes that do not create added value in production or service provision must be abolished. Therefore, the system only produces what customers want.

Just In Time was developed and perfected by Mr. Ohno Taiichi of Toyota. He developed this method to meet customer requirements in the fastest time. It can be said that JIT is a production management system in which the flows of raw materials, goods and products circulating in the production and distribution process are planned in the most detailed step by step so that the process The next process can be executed as soon as the current process terminates. Thereby, no item in the production process falls into a state of idleness or waiting for processing, and no workers or equipment have to wait for input to operate. The JIT system allows the system to operate most efficiently, avoiding unnecessary waste. Just in time aims to:

- Zero inventory;

- Waiting time is zero;

- The cost incurred is zero.

In the 1930s, Ford Motor Company (USA) first applied a line system to assemble vehicles, an early form of the Just in time (JIT) method. By the 1970s, Toyota Motor Company (Japan) perfected the above method and upgraded it to the Just in time - JIT theory. Japanese automobile company Toyota has developed Ford's production line system, promoting the advantages and overcoming the disadvantages of the above two production forms. A team of skilled workers is equipped with a flexible and versatile machinery system, capable of producing at many capacity levels with many types of products on the same line. The secret to Toyota's success is:

- Instant production – Just in time;

- One piece flow – One pieceflow;

- Self-check – Jikoda;

- Normalized average – Heijunka.

The Just In Time model is becoming increasingly popular and has been applied very successfully by many companies around the world. Among them, we can mention prominent businesses such as Apple, Xiaomi, Zara, Kellogg's, Tesla, etc. Despite the benefits of JIT, it can be difficult to manage in practice. The entire Supply Chain needs to be perfectly synchronized from A to B, which can understandably be a challenge with so many moving pieces. It requires manufacturers to accurately forecast demand in advance, so they know exactly what to send and when. In short, if a Company does not know the market, target audience and timeline for development, the JIT method can lead to serious stagnation.

What are the current conditions for applying Just in time (JIT)?

The Just In Time strategy is most effectively applied to businesses with repetitive production activities. The Just in time model has the following important characteristics:

- Using the Just in time model requires close coordination between Manufacturers and Suppliers. Strengthening social division of labor through cooperation with affiliated companies;

- They are responsible for checking and accepting the delivered products for sale before performing their work. Products that do not meet requirements will be removed from the line and reported to the entire System for timely adjustment of plans;

- The flow of "goods" circulates when the production and distribution process is detailed step by step so that the next stage can be performed immediately after the previous stage is completed. No workers or equipment have to wait for incoming products;

- Each stage only makes a quantity of products/semi-finished products exactly equal to the quantity needed by the next production stage. The worker in the next process is the customer of the previous process;

- To succeed in Just in Time, businesses need to synchronously combine many measures: apply a one-product flow line (products are transferred according to the production process, not according to specialized departments to minimize transportation costs). ), ability to self-check errors (post-test stages, acceptance of previous stages), standardization (distribute work evenly every day, no too busy days, no days with little work);

- Applicable to small batches of nearly the same production scale, receiving materials throughout the production process is better than producing large batches of goods and leaving them in inventory, stagnating capital. It also makes it easier to check quality, reducing damage when errors occur.

📦 Hotline contact shipping

🧭 Central

How to apply JIT most effectively? For example?

Once you know what JIT is, learning how it works to apply it effectively is really necessary for every business. Many business owners use the JIT method to increase efficiency and reduce waste by only receiving goods when they are needed for the production process, helping to reduce inventory costs. Therefore, this method requires manufacturers to accurately forecast demand to be effective.

For example, Just-In-Time manufacturing applications appear in many industries but mainly in those that use production lines or require raw material inventory. There are a number of companies that are very successful in applying the JIT system today, including Toyota, Apple and McDonald's.

Examples of Just in time production applications of some businesses

* TOYOTA:

Toyota was the first Company to implement JIT very effectively in 1970 and remains one of the most successful Companies in applying the JIT system. In this method, also known as Toyota manufacturing strategy, raw materials are not stockpiled and sent to the manufacturing plant unless an order is received from a customer and the product is ready to be manufactured.

Even throughout the production process, component parts are only used when required and only at certain production nodes/stations. This keeps inventory to a minimum, thus reducing costs. This also allows Toyota to adapt quickly to customer needs, significantly reducing the risk of having too much inventory. Important factors in Toyota's success:

- A small amount of raw materials is kept at each production station, ensuring that there is always enough stock to start production of any product;

- Accurate forecasting to stock raw materials at accurate levels.

* APPLE:

Technology giant Apple has also taken advantage of JIT principles to optimize its production operations. Apple's approach to JIT is different in that it leverages its suppliers to achieve JIT goals. Apple only has one central warehouse in the US, about 150 main suppliers worldwide; But the company has developed strong relationships and effective strategies with its suppliers. This outsourcing of production makes Apple leaner and thereby helps cut costs and reduce excess inventory.

With only one central warehouse in the US, the majority of the company's inventory is in retail stores. Also with JIT, Apple started taking advantage of dropshipping. This therefore reduces transportation costs, wastage and storage costs. Important factors in Apple's success:

- Responsibility for storage rests with the Suppliers;

- Leverage retailers as inventory systems;

- Arrange dropshipping for online purchases.

*MCDONALD'S:

Fast food chains like McDonald's use JIT inventory to serve customers on a daily basis. These fast food restaurants usually have all the necessary ingredients on hand, so it's only when an order is received that McD's actually "produces" its meals (with the exception of some finished products during peak times). ). JIT helps standardize processes so that every time a customer receives an order, they get the same consistent experience. Important factors leading to McDonald's success:

- Standardized procedures ensure consistency;

- The JIT method increases customer satisfaction because products are served immediately.

Benefits of applying Just in time

- Reduce warehouse area;

- Minimize the phenomenon of inventory and capital stagnation;

- Reduce scrap and defective products;

- Increase productivity by reducing waiting time;

- Increase product quality;

- Workers are deeply involved in improving and improving productivity and product quality;

- Flexibility in changing production processes and changing product designs;

- Reduce customer pressure;

- Reduce indirect labor.

JIT will contribute to eliminating the following types of waste

- Waste due to overproduction or too early;

- Waste due to transportation;

- Waste due to waiting;

- Waste due to excessive storage;

- Waste due to waste products;

- Waste of materials during production;

- Waste due to redundant movements or activities.

>>See more: What is car parking?

Should you choose to send goods interprovincially by truck or Container Proship to ensure cheap, fast and safe prices?

PROSHIP JOINT STOCK COMPANY recognizes the increasing demand for sending domestic goods to provinces and industrial parks, so it gradually develops and provides customers who are Individuals and Businesses with road freight transport services by container trucks. and trucks; Railway container transportation services; Sea freight services; Refrigerated container transportation services for seafood, cosmetics, medicine,...; Transportation services for LCL cargoes, bulk cargoes, special cargoes, and oversized and super heavy cargoes; Multi-modal project cargo transportation service. With the motto "Save costs - Improve efficiency - Professionalism at every step - Close connection - Door-to-door delivery" .

Up to modern times, our flexible and creative Transport and Logistics operating model has received trust from a large number of partners/customers/customers from North to South for many products/product groups. Different types of transportation, serving diverse purposes from consumption to production - business, supplying raw materials to Factories, Enterprises, and small business units. In particular, if you choose to send cheap parcels by truck, you will be committed to a newly invested vehicle with a hydraulic lift to help improve transport capacity as well as ensure absolute safety throughout. moving process.

When sending retail goods, combined goods, or whole shipments at Proship, customers can completely trust us because we are equipped with multi-load transport vehicles including 20-foot, 40-foot, 45-foot Containers; trucks of 5 tons, 8 tons, 10 tons, 15 tons, ... and many types of specialized vehicles transporting oversized and overweight goods from one location to another. The warehouse system is arranged in convenient locations for goods in/out such as Ho Chi Minh City, Binh Duong, Dong Nai, Hanoi, and Da Nang. Worth mentioning, we always have a very scientific inventory management plan, by all means not to prolong storage time at the wharf or yard. Commitment to "goods arrive, arrive at destination" , accurate delivery and receipt progress.

Receive deliveries in provinces and industrial parks from North to South

* Delivery in Northern provinces:

- Northwestern Provinces: Lao Cai, Yen Bai, Dien Bien, Hoa Binh, Lai Chau, Son La;

- Northeastern Provinces: Ha Giang, Cao Bang, Bac Can, Lang Son, Tuyen Quang, Thai Nguyen, Phu Tho, Bac Giang, Quang Ninh;

- Red River Delta: Bac Ninh, Ha Nam, Hanoi, Ha Nam, Hai Phong, Hung Yen, Nam Dinh, Thai Binh, Ninh Binh, Vinh Phuc.

* Delivery in the Central and Central Highlands provinces:

- North Central Provinces: Thanh Hoa, Nghe An, Ha Tinh, Quang Binh, Quang Tri, Hue;

- South Central Provinces: Da Nang, Quang Ngai, Quang Nam, Binh Dinh, Phu Yen, Khanh Hoa, Ninh Thuan, Binh Thuan;

- Central Highlands Provinces: Lam Dong, Gia Lai, KonTum, Dak Lak, Dak Nong.

* Delivery in Southern provinces:

- Southern Provinces: Binh Duong, Dong Nai, Binh Duong, Binh Phuoc, Vung Tau;

- Mekong Delta Provinces: Long An, Soc Trang, Bac Lieu, Tra Vinh, Tien Giang, An Giang, Hau Giang, Ben Tre, Ca Mau, Can Tho, Dong Thap.

* Or delivery at major industrial parks in Vietnam:

Phuoc Dong, Duc Hoa III, Nhon Hoi Binh Dinh, My Phuoc 3, Tan Khai, Minh Hung, Dong Xoai, Tan Phu Trung, Ham Kiem, Binh Thuan, Bau Xeo, Loc An - Binh Son, Giang Dien, An Tay, Bim Son, Long Duc, Du Long, An Hoa; Long Huong, Tam Diep II, Tram Vang, Cat Trinh, My Yen – Tan Buu – Long Hiep; Khanh Phu, Ba Thien 2, Nhon Hoa, Yen Phong II, Cong Hoa, Dong Anh, Soc Son; Ascendas – Protrade, ITAHAN, Ong Keo, Long Khanh, Dau Giay, Thanh Duc Industrial Park, Song Cong 2 Industrial Park, North Dong Phu Industrial Park, Thuan Yen Industrial Park,…

Proship accepts shipping of a variety of items

* Regular and dry goods:

- Transporting manufactured, consumer goods, and cosmetics;

- Transporting advertising goods and handicrafts;

- Transportation of home and construction furniture;

- Transporting heavy, bulky, heavy-duty goods;

- Transporting industrial and mechanical products;

- Transporting all kinds of chemicals;

- Transporting fabric, clothing, and leather shoes;

- Transporting manufactured, consumer goods, and cosmetics;

- Transporting packaging paper and carton products;

- Transporting fragile and perishable goods;

- Transporting auto and motorbike spare parts...

* Types of cold goods:

- Transporting fresh seafood: Shrimp, crab, fish, clams, oysters, snails, mussels, and other seafood;

- Transporting meat and meat products - fresh or frozen;

- Transporting fruits and vegetables - unprocessed or processed;

- Transporting dairy products: Fresh milk, yogurt, whey, milk cream;

- Transporting vaccines, medical drugs, and test samples;

- Transporting water and special solutions.

The knowledge Proship has conveyed above, hopefully has helped businesses understand what JIT is? What are the conditions for applying JIT (Just in time) as well as how to apply JIT most effectively. Along with that, any unit that is looking for a carrier, door-to-door delivery with safe and flexible storage solutions can update key information about related services to know if Proship Joint Stock Company has Does it meet the criteria you set? Please continue to follow the next series of specialized terminology articles and contact 0909 344 247 when you need to send goods to the province by safe, cheap containers or trucks.